Probably the most serious cause of accelerated degradation or deterioration of the integrity of a reinforced concrete bridge deck is corrosion of the reinforcing steel. It is common knowledge that when regular health monitoring and maintenance is delayed or eliminated on these structures, they inevitably deteriorate or fail prematurely. This makes any repair, rehabilitation or replacement decision more critical and costly, because deterioration is typically at an advanced stage.

Even a good visual inspection program alone does not uncover many early indications of distress that, if discovered, treated, or repaired early, can slow or effectively halt the rapid advance of deterioration. Many of the underlying factors contributing to deterioration cannot be seen. These factors include the variability in (a) rates, amounts, and locations of chloride intrusion into the protective alkaline coating that the concrete affords the steel; (b) concrete depth from surface to top mat of reinforcing steel in small, localized areas and throughout the deck that contribute to accelerated corrosion or corrosion "hot-spots"; (c) shrinkage cracking "built into" the deck, often caused by high variability in cover and/or excessive cover, providing direct pathways for entry of chlorides through the protective concrete to the reinforcement; (d) quality of concrete materials and placement, as well as finishing, which can affect initial concrete integrity or permeability; and (e) condition of asphalt or other overlay and membrane, or presence of older repairs.

Geophysical methods, used properly, can be very effective to accurately measure some of these parameters, inferring others from the measurements made at or near the deck surface, and significantly enhancing traditional bridge deck evaluations. Unfortunately, geophysical methods are employed quite often when results obtained from other deck evaluations fall short of expectations, or seem inconclusive, i.e., either deterioration quantities are dramatically over- or under-estimated or are suspect, which can result in poor decision making. At such times, geophysics can be very useful, but often it is applied too late and at a time when budgets are already strained.

Geophysics provides its greatest potential benefit at the early stages of diagnosis. Very often, geophysics (NDT) is not employed because other nondestructive, highly subjective techniques, such as chain-drag and hammer-sounding used to identify delamination in decks, are used. They are also considered by many to be good tools for early diagnosis and timely treatment of concrete that has been damaged by corrosion simply because their results are straightforward. They do find damage in a deck when it is quite deteriorated, and they locate the worst surface damage quite well. However, they absolutely are not early-stage diagnosis methods, and are ineffective tools in early-stage diagnosis or detection of problems that should be addressed before deterioration becomes advanced. At that time, chain-drag and hammer-sounding can play a useful role in identifying severely damaged regions on the deck, or they can be used for comparative purposes to illustrate that late-stage damage is being detected by other means.

These two NDT (not geophysical) techniques cannot identify a deteriorated state in concrete that is indicative of early-stage, or onset of internal corrosion; rather, they reveal to some extent the regions within the deck where corrosion is so advanced that more extreme measures must be taken to repair, rehabilitate, or replace the deck, and they are extremely subjective and susceptible to influence from noisy conditions, such as nearby traffic. More realistic early-stage evaluation or screening methods are available, and should be employed at regular intervals.

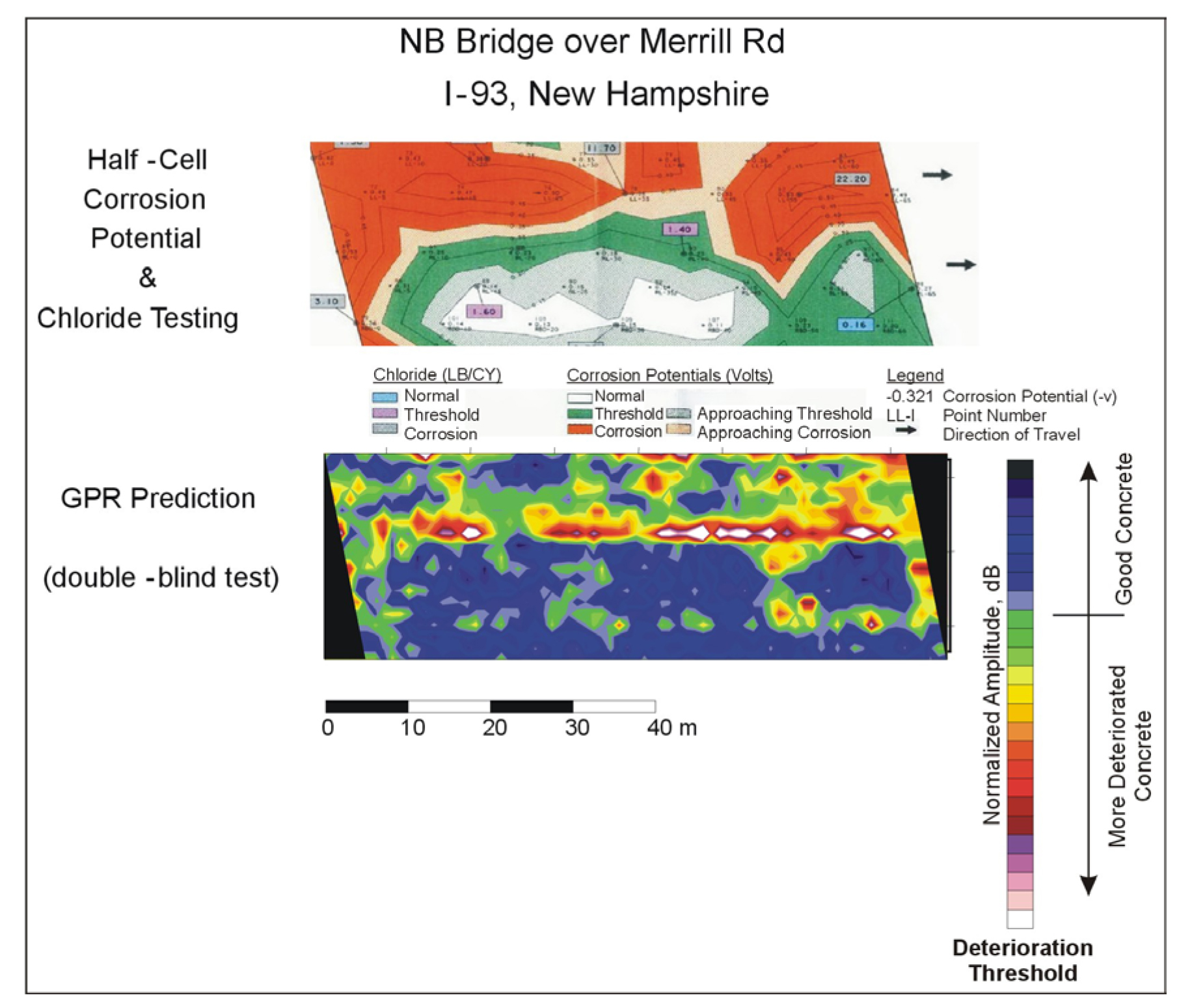

Figure 69 shows the results of two geophysical surveys. Blue regions on GPR map indicate normal condition. Light blue indicates deterioration threshold with progressively increasing deterioration indications (green, yellow, red, etc.). On the half-cell map, bright orange indicates active corrosion, tan indicates approaching active, green is threshold, gray indicates approaching threshold, and white is normal. Sampling density on half-cell tests is approximately 30-cm spacing between samples. Chloride results support half-cell results and GPR, for the most part (too small to be seen on this image).

Many times, appropriate geophysical (NDT) methods, such as electrochemical methods, GPR, or ultrasonic-seismic tools, are used simply because they are specified in a given project. By default, the geophysical "experience" is often less than desirable because it is likely to fall short of customer expectations, often because desired results are unrealistic and/or non-existent, or the evaluation is viewed as an unnecessary burden. This typically results in searching for the lowest cost NDT survey method available to meet the "requirement"; and even if a relevant NDT tool is selected, the scope of work is generally not well thought out or designed prior to solicitation of bids. When factors such as traffic control are considered, on top of the ineffectiveness or failing of a poorly selected or designed NDT program, the lowest cost often becomes more expensive than more effective techniques.

Figure 69. Geophysical method results (Ground Penetrating Radar and Half-Cell Corrosion Potential contour plots) from double-blind test.

Ground Penetrating Radar (GPR)

GPR systems are in regular use for mapping corrosion and debonding on bridge decks. See Ground Penetrating Radar (GPR) for further discussion. For vehicle mounted GPR systems, please refer to Vehicle Mounted Ground Penetrating Radar Systems.

In this application, GPR image character changes often correlate very well with areas of corrosion of rebar and debonding. It is important to note that GPR cannot identify or verify that corrosion is actually taking place, confirm that rebars within the deck are losing steel mass, or measure or predict the amount of cross-sectional loss in the steel at any given location. However, GPR has several strengths that lend itself to being used as the best method for initial screening for identification of the presence and/or degree of corrosion within a deck.

Half-Cell Corrosion Potential

A separate geophysical method includes a semi-destructive (for the most part, nondestructive) electrical technique for assessing potential for corrosion in existing deck structures, and is based on measuring voltage (electrical potential) between the anode (top mat reinforcing bars) and a reference electrode.

Galvanic cells form within regions of the deck that differ significantly in their level of corrosion activity. The half-cell potential method is based on the principle that variations in corrosion rate (activity) among these localized regions, or cells, cause electrical current to move through the deck and are proportional to the electrical potential between the reinforcing steel and the deck surface. This measured potential (mV) is thought to be proportional to the loss of steel mass from the reinforcing bars at any given location within the deck, and can be used as a reliable predictor of corrosion states that exist, particularly when PPD of rebar are well-established.

The anode connection is typically a direct one (electrical clamp) with a wire lead to the instrument, meaning a small hole has to be drilled into the concrete to secure to provide direct electrical contact to the reinforcing steel. The reference electrode is electrically coupled to the bridge deck surface using a copper-sulfate solution in which the other lead is suspended, and a sponge at the bottom of the container (holding the copper-sulfate and suspended reference electrode) allows copper sulfate solution to provide good electrical contact with a clean deck surface.

Measurements of electrical potential (voltage, mV) are obtained at discrete sampling intervals across the length and width of a deck, directly over rebar at known depth. Local variations in rebar depth near each sample location are desirable so that they can be factored into a more precise analysis, as a contour plot of the potential readings is prepared. These potential levels are used to characterize "activity" levels (corrosion states) existing beneath the surface of the deck. The voltage reading at each location, in mV, is interpreted to signify an indication of the likelihood that corrosion activity is at or near pre-determined levels, or corrosion states.

It is best used in combination with other methods, as summarized below, to obtain optimum results:

- GPR can be used to provide information about overall condition of the deck, indicating most likely locations (and severity levels) of deterioration-so that half-cell measurements can be focused to specific regions rather than used to characterize an entire structure; this is a very economical approach to use, particularly when large decks or a multiple number of structures are to be characterized. GPR also provides complementary PPD information about the rebar in the deck, directly useful as input into the half-cell corrosion potential analysis.

Other electrochemical methods, e.g., acoustic emissions, etc., either estimate (and verify) corrosion activity level, or provide fairly good estimates about the corrosion rate of steel at specific areas within the deck.