Concrete condition can be broadly defined as the following: (1) Concrete in good condition typically is free from, or has relatively minor indications of, internal corrosion-related problems as evidenced by visual inspection, mechanical testing, chemical sampling or petrography, acoustic (geophysical) methods, electrochemical testing and analysis, and/or investigations using ground penetrating radar. (2) Concrete is also relatively strong, mechanically, shows little evidence of damage or even cracking, appears very durable after considerable exposure to traffic and the environment, and is free from any significant defects in design, materials, and workmanship or loading. Again, this is evidenced by visual inspection, mechanical testing, chemical sampling or petrography, acoustic (ultrasonic-seismic) methods, or investigations using ground-penetrating radar.

Although corrosion can definitely be caused or exacerbated by the quality of construction, it is mostly a product of two mechanisms: corrosion induced by entry of chlorides into a concrete deck from the top surface because of application of de-icing chemicals, and corrosion induced by entry of carbon dioxide into warm, moist concrete, which forms carbonic acid and causes corrosion to accelerate due to a process known as carbonation. The end result is typically cracking, delamination, and spalling of concrete as it detaches from the reinforcement mat(s) within the deck and seriously affects the ability of a structure to reach its design life if measures are not taken to periodically monitor the internal, electrical, and chemical changes that have taken place.

Moisture entry into the concrete and its retention, moderate-to-high temperatures, and availability of oxygen provide the raw materials and conditions required to enhance corrosion activity. The complete lack of oxygen or moisture in a structure is enough to halt it, but this is typically not a realistic scenario.

Concrete that is well designed, contains high-quality materials, has a low water-cement ratio, and properly designed and entrained air content experiences relatively few problems when it is well maintained (preventively) and its condition is regularly monitored. Other factors that can determine the design life of concrete include whether the concrete was well placed, properly vibrated, finished, and cured in a structure where care was taken in fabricating the reinforcement in a uniform fashion according to specifications, and formwork was installed carefully as part of the construction process. Its initial condition-quality and integrity, strength and durability, appropriate and uniform cover-will ensure that the protective, alkaline concrete barrier surrounding the steel prevents early entry of chlorides, provides a difficult path for entry of water and oxygen into the concrete, and endures damage from cyclic, flexural loading that induces cracks into the concrete surface or freeze-thaw damage caused by daily extremes in temperature above and below the freezing point of water. In short, its quality prevents excessive damage to the structure. Without initial quality assurance or baseline condition assessments using the appropriate full-coverage NDT method, however, initial quality is unknown.

Effective baseline condition evaluations include GPR and ultrasonic-seismic methods, properly designed so that they will duplicate future assessments used for diagnosing concrete condition/integrity as the structure ages. Once the structure is in-service for 5 to 10 years and before chloride intrusion has a chance to encounter the steel, a follow-up diagnosis, performed exactly like the first one, but perhaps including additional NDT and/or ground truth, must be performed to ensure early detection of any problems. If the initial baseline assessment indicated any structural defects, flaws, significant variation in concrete cover, or deviations in rebar PPD from design, earlier secondary diagnoses may be warranted.

Regardless of when serious NDT methods are employed on a regular basis for monitoring the health of a structure health as it degrades, the cost-effectiveness of early detection far outweighs the price paid in repairs, rehabilitation, or replacement during the life of any structure. The sooner the baseline and follow-up diagnostic schedule begins, the greater its impact and long-term, economic benefit will be.

Regular evaluations will also ensure that the structure is properly diagnosed each time a preventive maintenance measure is decided upon and implemented, removing almost all the concern about NDT evaluation limitations that exist when NDT is asked to diagnose a structure only when it is in a serious state of deterioration. These evaluations should always incorporate some degree of ground truth analysis, even if more limited at first.

Appropriate NDT never costs millions over the life of a structure; repairs and lost service life do. Ineffective diagnosis and timing are typical, not unusual, of current diagnostic practices, as well as the failure to use the best preventive NDT measures in the right manner during the life of a structure.

Two common nondestructive, acoustic, methods are widely used to assess the concrete integrity in existing decks and to determine the extent and quantity of deterioration. This information will be factored into an evaluation of its condition state and ultimately lead to a preventive or corrective maintenance decision. These two methods are chain dragging and hammer sounding, where either a heavy chain at the end of a hollow pipe is literally dragged across a bare concrete deck, or a rock-hammer or similarly designed hammer is used to repeatedly strike its surface. Both require the user to detect delaminations by the change in pitch or qualitative "thunk" that the instrument makes as it is used to test the integrity of the deck.

Both are highly subjective, vary from one operator to the next, and are subject to changes in environment (noise, like traffic). "Hollow-sounding" areas are marked on a deck with paint, and their respective sizes and locations are drawn onto a plan-view map representative of the surface area of the deck.

Unfortunately, however, because the "chain-drag method" is simple to use and understand, and it does identify definite serious damage on the deck, it is erroneously viewed as the "standard" by which to evaluate other methods that are typically more responsive to early-stage detection of deterioration. When another NDT method reports deterioration that the chain-drag does not confirm, the other method is considered flawed.

Ground Penetrating Radar (GPR)

The preferred method for identifying regions where deck deterioration is taking place, and using that information to guide evaluation is ground penetrating radar (GPR). For vehicle mounted GPR systems, please refer to Vehicle Mounted Ground Penetrating Radar System.

GPR should not be assumed to be directly sensitive to or even geared toward direct identification of delaminations, even though it is often misrepresented that way. Therefore, it is often deemed inappropriate for identifying the onset of deterioration even if it identifies larger areas of deteriorated concrete that include many individual delaminations.

In this case, GPR is said to "overestimate" delamination, when in reality it is helping identify areas that are already seriously degraded and will become either delaminated or otherwise deteriorated in due time. At other times, when a chain-drag or hammer sounding identifies a defect or delamination, GPR "misses" delaminations or spalls caused by means that are not corrosion-related (see discussion on incipient spalling in Incipient Spalling). When it misses "delaminations," it is deemed unable to detect deterioration within the deck.

Not all delaminations are caused by electrochemical processes that GPR is sensitive to, and GPR is not suited toward identifying the symptom (delamination, crack, or spall) that results from these various deterioration mechanisms (refer to concrete condition in Concrete Condition/Integrity.

GPR does not detect delaminations themselves in decks, unless they are extremely shallow, air-filled, and very thick (0.6 cm) or more. At that thickness, they would already be detectable by other means, loose, or reflect spalled areas that have simply not yet 'kicked out' of the deck surface. Even at 0.6 cm or thicker, these air-filled delaminations are not easy to identify as such. GPR will only measure delaminations directly at about 0.3 cm or thicker and completely water-filled. Water slows down the signal enough so that GPR is responsive to its presence, and it also causes the reflection from a thick enough delamination (water-filled) to be imaged or seen more directly in the data.

What GPR does do well, and why it is valuable in detecting both the onset of deterioration or advanced stages of it is respond to electrical changes in deteriorated or chloride-infiltrated concrete that result from (a) chemical changes in the concrete that cause its dielectric properties to vary from place to place, and (b) changes in electrical properties of the deck (electrical conductivity) that cause GPR to either reflect more energy back toward the surface at an abrupt, conductive interface, or disperse the signal (attenuate it) more rapidly so that little or none can return to the surface to be measured. Moisture variations in the deck associated with corrosive conditions, particularly when a conductive environment is present or electrically conductive agents (such as chlorides) have infiltrated, are also picked up by GPR.

Each of these variables within the deck that changes or affects how a GPR signal propagates through it and modifies how it reflects or penetrates at various material boundaries, contributes to signal variation that can be measured and compared at every location the GPR survey samples the deck. What makes GPR so valuable then is that it is an indicator that can identify quantities and locations of impending or advanced corrosion conditions that will cause the following: (a) reinforcement to corrode, (b) concrete integrity and chemistry to change, and (c) damage (such as cracking, delamination or spalling) to concrete.

The ability of GPR to detect cracking, delamination, or spalling directly is coincidental to its ability to identify impending and advanced corrosion-related conditions within the interior of a deck and identify where they most likely exist. If used properly, it can perform these tasks extremely well. However, it is best used in combination with other methods, particularly acoustic ones like ultrasonic-seismic geophysical methods (SASW/impact-echo), as part of a regular inspection process that diagnoses early stages of deterioration so that preventive measures and maintenance can be taken or applied at the appropriate times in service life of a deck.

The main tools for concrete condition evaluation are seismic methods and GPR. USW, SASW and IE methods can be used to measure modulus and stiffness of concrete. In some cases, it may be useful to employ GPR as a rapid reconnaissance to qualitatively find problem areas that can then be studied in more detail with seismic methods.

For detailed description of these methods in this application, please refer to Spectral Analysis of Surface Waves Methods and Multchannel Analysis of Surface Waves Methods - Pavements.

Impact Echo (IE)

For detailed description of Impact Echo in this application, please refer to Impact Echo - Pavements.

Interpretation: Impact Echo data are interpreted for depth associated with the resonant frequency, just as in other applications. In the case of condition measurements, cracks or debonding within the concrete layer will show up as depths that are much too small to match the whole thickness of the structure.

Advantages: This method provides depth to the first break in the concrete. In the case of old concrete, identification of an impact echo break at less than the structure's original thickness indicates cracking, or some other problem.

Limitations: Interpretation of the breaks measured is not always straightforward. Also, this technique only identifies major problems such as cracks debonding.

Surface Wave Methods: SASW/MASW and USW Spectral Analysis of Surface Waves (SASW)/Multiple Channel Analysis of Surface Waves (MASW) and Ultrasonic Surface Waves (USW)

For detailed description of these methods in this application, please refer to Spectral Analysis of Surface Waves and Ultra Sonic Surface Wave Methods - Pavements.

Another grouping of geophysical techniques measures initial concrete condition (thickness and/or integrity) by integrated ultrasonic-seismic methods:

- Spectral analysis of surface waves (SASW), where ultrasonic body-waves (UBW) and ultrasonic surface waves (USW) are used to determine mechanical properties of the concrete using an impact source and two sensors-so that propagation velocity of the sound energy can be determined-allows elastic and shear moduli to be calculated, assuming a value for Poisson's ratio and a relationship between the P- and S-wave velocities in concrete (reliable assumptions to make based on knowledge of the design strength). Stiffness (integrity) and strength can then be determined for deck structures, and can be verified by some destructive sampling, if required.

- Together with Impact-Echo (IE) methods, an impact source and a single sensor can determine travel time between the top and bottom surfaces of a deck, or to and from an internal defect or around it to (a) measure deck thickness, and (b) establish deck integrity. These methods are useful during a QA evaluation on a new structure, as part of a baseline survey for comparison with future tests, or as part of a comprehensive condition assessment on an existing deck.

- Utrasonic seismic devices, such as the Portable Seismic Pavement Analyzer (PSPA), can be successfully used to assist in evaluating bridge deck condition, alone or in tandem with other geophysical and/or ground truth sampling (see figure 79 and figure 80). It is always recommended, however, to use a multiple-method approach.

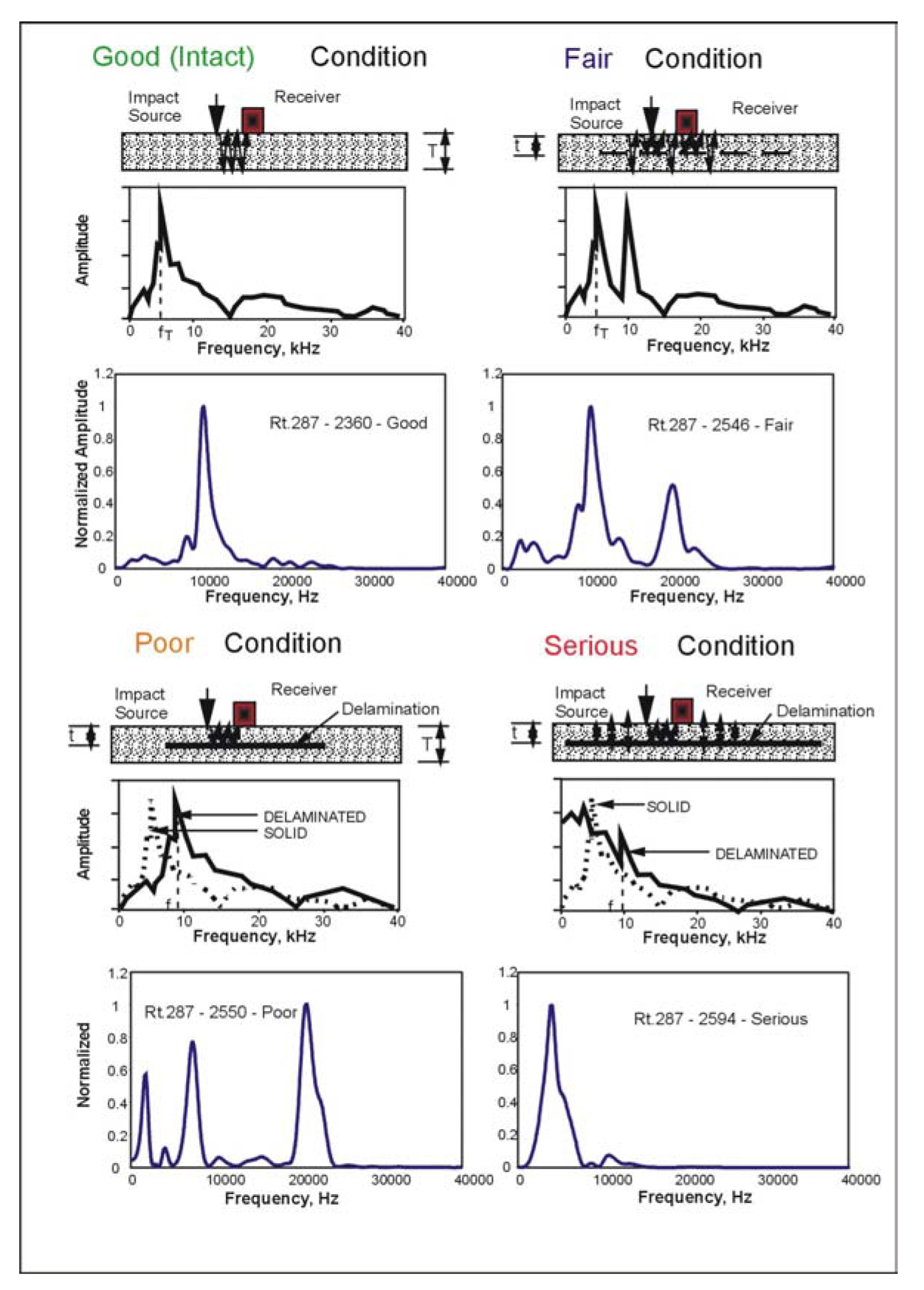

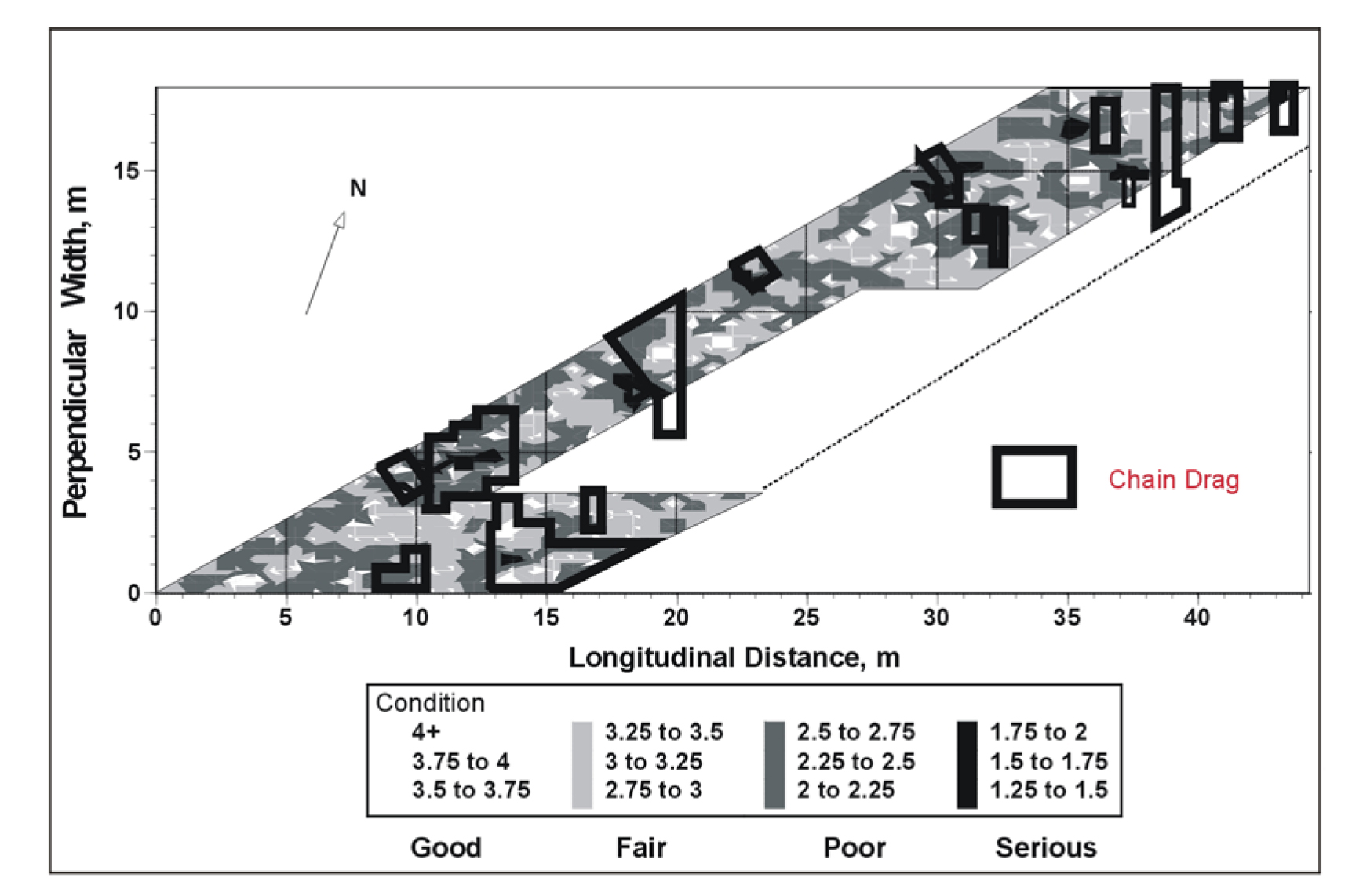

Ultrasonic-seismic methods, like impact-echo and SASW used in combination, are very useful at identifying already-damaged locations in the deck (see figure 70). Unlike chain dragging and hammer sounding, these geophysical methods identify this damage at early, moderate, and late stages of development. The common "NDT" methods of chain dragging and hammer sounding only detect those flaws that have developed to an advanced stage, and they finally become audible to the human ear. Effective preventive maintenance and/or treatments, such as cathodic protection, should already have been performed by the time these methods reveal problems.

Furthermore, localized repairs identified directly by hammer-sounding and chain-dragging are limited to application on smaller regions than the deteriorated zone(s) causing these defects, particularly when corrosion is what initiated the problem. Repeated maintenance at or near the same locations as previous maintenance applications indicates that the methods used to identify the deterioration are insufficient, and require a better ability to identify early-stage and moderate-stage development of mechanical failure.

Figure 70. Portable Pavement Seismic Analyzer (PPSA) correlated to initial, moderate and severe delamination development (fair, poor, serious), respectively. Results plotted on plan-view map and compared with chain drag results.

These ultrasonic-seismic techniques perform that task well; however, they do require lane closure as do chain dragging and hammer sounding. Sampling (although relatively speedy, considering the quality of the end-result) at lower speeds with any degree of efficiency or close proximity from sample-to-sample, can be a bit time-consuming when compared with a method like GPR. However, these methods can identify mechanical defects (like delaminations and incipient spalls) to confirm GPR-predicted deterioration interpretations, and they complement GPR in local regions where these defects may have been caused by mechanisms not related to corrosion.

A better approach is to survey the entire deck with GPR (preferably either Method One or Two), and focus on identifying locations on the deck where these ultrasonic-seismic methods can be applied. Characterizing a few, smaller regions using these acoustic methods will allow for a comparative analysis of the results (GPR and ultrasonic-seismic) to be performed. It will also reveal the extent or degree of severity of mechanical damage that exists outside the regions identified by the GPR prediction.

This information can also be useful in identifying other deterioration mechanisms (perhaps alkali-silica reaction, defects caused by materials and workmanship, design flaws, mechanical damage due to a combination of the above, and repeated cycles of loading) that are likely causing some of these defects. This should prompt further discussion on how the deck condition should be investigated to uncover the root causes of other problems that are nearly as significant, or even more so, as any corrosion-based problems.

Interpretation: In bridge deck applications these methods are used to measure modulus just like in pavement applications. The purpose is to get a good quality measurement of modulus. Degraded concrete will give a lower modulus measurement. Problems can be identified early with these techniques since action can be taken before major failure occurs based on degrading modulus measurements, especially if periodic assessments are done for comparison over time.

Advantages: This method gives concrete quality without coring.

Limitations: None.

Combined Approach

The two methods mentioned previously can be used in much the same way that a combined GPR/coring or GPR/sounding evaluation is approached. The results of the localized sounding, performed in regions that represent the total degree of variability identified within GPR contour plots, but in a relatively small, localized area with respect to the total size of the deck, are used to verify and/or complement GPR interpretations of deterioration threshold levels on the deck. Initial, moderate, and advanced stages of delamination should correlate to some degree with the contour plots on a plan-view GPR presentation of the surface of the deck. By analyzing and comparing the two, appropriate deterioration threshold(s) can be selected from existing contour plots on the GPR map and be used to designate boundaries where relatively sound concrete meets locations that are undergoing either severe, moderate, or initial deterioration.

Incorporating the mechanical (acoustic) analysis into the results obtained by the full-coverage, electromagnetic one results in a very good-to-excellent, prediction tool (figure 71). This final interpretation can be used very effectively as a baseline condition assessment early in the life of a deck, a later investigation several years into the future whose purpose is to identify the onset of deterioration, or a condition assessment used to identify the degree and severity of corrosion already existing beneath the surface of a deck.

NDT surveys should be performed so that full-coverage, objective screening tools that best identify the predominant conditions existing when deterioration manifests itself (GPR) are followed by geophysical (NDT) methods best-equipped to identify defects that exist after this "condition state" is serious enough to cause damage (ultrasonic-seismic).

Figure 71. Condition levels obtained by using integrated Ultrasonic-Seismic method.