Baseline condition assessment is not a routinely practiced form of quality assurance; however, it is truly the only way to compare the overall as-built condition of a structure to its future condition at various stages during its life. One way to establish a baseline condition where "as-built factors" (variables in materials and workmanship that often hamper or adversely affect the accurate diagnosis of the condition of a structure) can be eliminated or minimized from consideration during a future evaluation is to perform measurements on a new structure identical to those that will be used for primary "screening" in the future to diagnose its overall condition.

To establish a baseline condition assessment, only nondestructive evaluations are of value, and only those that continuously sample the deck along every centimer or meter of its length and width in the manner highlighted above warrant consideration. That leaves only "full-coverage" methods, such as GPR, SASW and impact-echo, infrared (IR) thermography, or electrochemical analyses as candidates for this approach.

GPR will accurately measure initial presence, pattern, and density of the reinforcement layout, including cover (depth) of reinforcement and any overlay properties. Initial data can very easily be collected in such a manner that it will be identical in scope to data collected during a future deterioration-mapping process. Additionally, it will provide repeatable and accurate condition assessment results in a more consistent fashion than any other NDT method at any stage of the life of a structure. Collecting the data is rapid, fully nondestructive, and straightforward once an established methodology is developed and adhered to; the data can be obtained on decks with or without overlays that protect the concrete surface to establish their effect on its initial and future condition states.

When factoring in economics, objective capability and repeatability of the measurement, effective deck coverage, and ability to collect the baseline data without the absolute need for other NDT or destructive sampling, GPR is the only sensible instrument to use for this screening process. It may be advantageous, however, to complement the GPR screening with diagnostic evaluations of a baseline nature in regions where the GPR or past experience reveals conditions (reinforcement depth, variations in depth and layout, or other heterogeneities not designed into the structure) typically indicative of potential problems in the future. Those targeted areas can be measured, and the data obtained can be compared with future information gathered from those precise locations to supplement, verify, or otherwise improve a future GPR-based condition assessment

A geophysical survey method that provides useful, objective information about the relative condition of the various areas on a deck structure and samples the entire deck in a rapid and economic fashion is generally most valuable when it is used prior to making other important decisions. These include decisions on whether other NDT, destructive sampling, or laboratory testing and analyses are needed to provide a better evaluation, or choosing between complementary evaluation techniques, whether the deck structure is new or old. If approached in this manner, geophysical techniques can and will supplement any traditional bridge deck evaluation. They add little to the overall price of diagnosing the structure, and the information provided will minimize the overall inspection, maintenance, or replacement costs associated with the structure during its service life. Geophysics also helps to ensure that the appropriate maintenance and preventive maintenance measures are applied at the right time.

Methods used in bridge deck condition assessment should be accurate, rapid, and nondestructive whenever possible, whether QA verification testing or existing bridge deck evaluations are the desired goal. The current practice of deck inspection (existing structures) by chain dragging meets only the last two criteria, and is not any more rapid than some other, more objective, nondestructive geophysical evaluation techniques. The accuracy of chain dragging is significantly compromised by the fact that it can only be used to identify delaminations at stages where the deterioration has already progressed to such an extent that major rehabilitation or repair measures are needed.

Similarly, the Pachometer barely meets the last two criteria when it is used as a primary instrument for verifying that QA specifications are being achieved on new deck construction, because it cannot typically achieve requirements that mandate measurement accuracy within 0.25 to 0.635 cm, and the measurements are not repeatable.

Identifying the appropriate NDT method, or methods, prior to some verification ground-truth (limited coring-both older and new decks--and/or chemical, physical or optical analysis of deck samples on older decks) is always the best approach toward effective use of these geophysical methods.

When used as a primary investigative method, either as a baseline condition assessment tool early on in the life of a structure or as a deterioration-mapping instrument, geophysics is often beneficial if used as a "reconnaissance tool" in the early stages of an evaluation. The results of the geophysical survey can be used to help (a) select complementary inspection methods, destructive or nondestructive, that would best complete the analysis; (b) reduce the quantity of destructive testing or NDT investigations that are more time-consuming and require lane closures, even if they are essential to the overall evaluation; and (c) limit these other tests to much smaller areas on a given deck. Information obtained by these other techniques will generally complement, validate, and/or "calibrate" the initial geophysical survey method.

A competent bridge deck condition assessment professional will understand the following rationale. One should remain skeptical of any single geophysical method used alone with the promise of an all-purpose solution to deck condition assessments and is recommended without supplemental evaluation, testing, or ground truth. However, sometimes new applications or methodologies can produce results that are more accurate and reliable than traditional approaches that have been widely used. Improvements in analysis capabilities or new ways to use both newer and older instruments should not be ruled out because few people have used them. Similarly, one should not be overtly dismissive of geophysical techniques based on one, or even a few, less-than-satisfactory personal or anecdotal experiences, particularly if they occurred several years ago. Some data analysis and processing techniques were still somewhat experimental or in their developmental stages. Advancements in computing capabilities, analysis software, and survey methodologies over the last 3 to 5 years have contributed to significant gains in the value certain g eophysical surveys add to bridge deck evaluations. Much of the subjectivity in interpretations has been reduced, minimized, or altogether eliminated.

Ground Penetrating Radar (GPR)

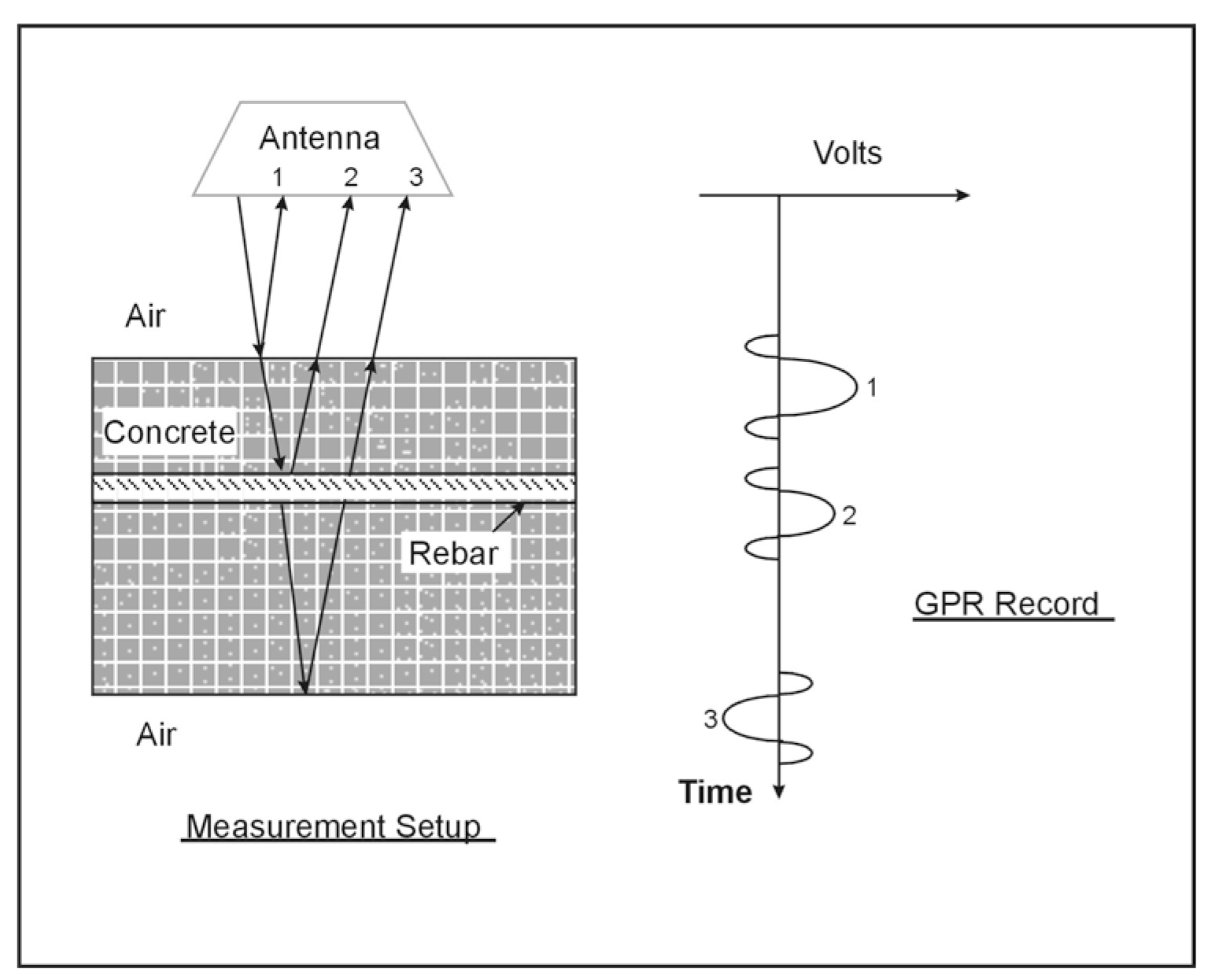

For detailed description of GPR (figure 66) in this application, please refer to Vehicle Mounted Ground Penetraing Radar (GPR) Systems and Ground Penetrating Radar (GPR) - Pavements. GPR is regarded as the most promising nondestructive geophysical method available for assessing bridge deck condition on both new and old structures. For this reason, much attention is devoted to treatment of this method, and additional references to pavement applications (not covered in this section) are provided, because much of the information is inter-related.

Figure 66. Horn antenna (air-coupled) setup and measurement: Basic horn antenna

setup

(single antenna) is used for bridge deck or pavement evaluation at high speed.

Individual Ground Penetrating Radar methods.

After a GPR survey has been completed using sound methodology, appropriate analysis software, and the results contour-plotted, GPR should be used to provide guidance on where to use other NDT methods on decks (and/or where to sample using cores or other destructive means). Controversy exists regarding GPR and its abilities, partially because some methodologies used in bridge deck survey analysis (a) are not technically viable, from a theoretical or a methodological approach; (b) rely on subjective analysis (visual) of the raw data, based on evaluating amplitude with simple color-threshold levels applied, and conclusions based on these visual observations; (c) improperly characterize GPR as a tool that is used to identify and detect delaminations (it cannot); and (d) unrealistically assume that a GPR survey is best used as a stand-alone tool to compare directly against other "ground truth" such as chain-drag or hammer-sounding. The capabilities of GPR and the value of its contribution to a deck evaluation are considerable when the methods are fully understood and properly applied, and realistic expectations for results are defined. This awareness will significantly minimize the number of occurrences where incorrect or inconclusive results characterize GPR's success. A three-step approach is recommended: (1) GPR is used to specify locations that are candidates for other NDT testing and analysis; (2) NDT surveys completed; (3) limited and targeted ground truth (destructive testing).

Comparison of Pachometer w/GPR

A less-used, but decidedly better technology for approaching QA tasks often specified for Pachometer evaluation, one that can provide baseline as well as future condition assessment on bridge decks, is ground penetrating radar (GPR), another electromagnetic (EM) method based on generation and measurement of EM emissions in the radio-frequency spectrum. GPR is rapidly becoming the most useful geophysical (NDT) method for Characterization of bridge deck condition or quality, whether the deck is newly constructed, or is in-service, as an existing deck that requires monitoring or extensive condition evaluation.

The Pachometer is not a recommended tool for QA verification of rebar PPD if accuracy and repeatability within 0.635 cm is consistently expected for quality assurance work. It should be used primarily for locating rebar in walls, floors, or decks prior to cutting and coring operations. Even then, it should be limited to uses where critical elements, such as conduits, post-tension steel, etc., are not present, or in situations where cutting through reinforcement does not pose a structural problem.

Because of these limitations, particularly when compared with more advanced and accurate instruments, discussion of Pachometers and similar instruments will be limited to this description and only few brief references within the text.

Electromagnetic (EM) Instruments Sensitive to Ferrous Content in Steel

A variety of nondestructive geophysical instruments can be used for these stated QA tasks. The most widely used instrument is the Pachometer, an electromagnetic (EM) instrument sensitive to ferrous content in steel and used to determine cover (depth to reinforcing steel from concrete surface), reinforcement quantity, and layout (spacing of bars and their lateral positions within the deck). However, the instrument is not accurate or repeatable enough to provide these measurements for verification purposes. Neither is it able to collect continuous data in a rapid fashion along the entire deck, while providing an initial (baseline) condition assessment of a deck for comparison to future evaluations.

This family of EM instruments is limited by its inability to differentiate between a single shallow reinforcing member and a closely spaced grouping of one or more bars. It is also limited in its ability to penetrate concrete more than 10 to 15 cm, in general. However, for quick verification of well-characterized structures (whose as-built drawings can be relied upon to provide accurate information about construction), Pachometers and other simple EM response instruments provide suitable accuracy for locating lateral placement and positioning of rebar and even determining depth. They are best used to locate reinforcement in (a) rehabilitation situations where cutting or coring into concrete does not involve the risk of damaging post-tensioned cables and ducts, electrical conduits, fiber-optic conduits, or other embedded utilities; and (b) structural analysis calculations where reinforcing is known to be spaced at fairly large and consistent intervals within the depth range that these instruments are suitably sensitive.

Ultrasonic-Seismic Techniques

It has been demonstrated that ultrasonic methods implemented in various forms of integrated ultrasonic seismic devices, such as the Portable Seismic Pavement Analyzer (PSPA), can be successfully used to assist in evaluating bridge deck condition, alone or in tandem with other geophysical and/or ground truth sampling. It is always recommended, however, to use a multiple-method approach.

Of special interest are three ultrasonic techniques: ultrasonic body wave (UBW), ultrasonic surface wave (USW), and impact echo (IE). These geophysical methods can be used separately or in combination. The first two are used in concrete Characterization (concrete integrity and/or determination of mechanical properties using basic assumptions about the relationships between P-wave and S-wave velocities), and the IE method is the primary tool in delamination detection once a propagation velocity (speed) for travel of the seismic wave in the concrete is established. The primary advantage that the IE method has over the current practice of chain dragging is that it allows detection of delamination zones in various stages of deterioration, from initial, through moderate, to and fully developed (incipient spalling).

As demonstrated by finite element simulations of two probable scenarios of delamination progression, periodic monitoring of bridge decks by IE enables improved prediction of deterioration processes in bridge decks. Three-dimensional data visualization techniques constitute important components in condition assessment and delamination detection using the IE method. Results presented include three-dimensional translucent visualizations of a bridge deck section, horizontal cross sections through all distinctive zones (including a zone of delamination), and vertical cross sections along chosen test lines. Visualization techniques enable the PSPA to be used as a kind of bridge deck sonar device.

The combined ultrasonic seismic techniques, however, do require more sophisticated analysis than (a) the GPR and half-cell corrosion potential methods (condition assessment of existing decks), or (b) the GPR or Pachometer (new structure PPD of reinforcement). This statement is not necessarily true on some of the QA applications, however, such as determination of concrete integrity on new and fairly uniform structures, where use of the acoustic techniques can be straightforward and very simple. An example of a simple impact-echo device used to measure concrete thickness, for example, is a concrete thickness meter that can accurately determine thickness for QA verification purposes.

For detailed description of Spectral Analysis of Surface Waves (SASW) and Ultrasonic Surface Waves (USW) methods in this application, please refer to Spectral Analysis of Surface Waves and Ultra Sonic Surface Wave Methods - Pavements.

Ultrasonic Seismic and Impact Echo (Combined)

Ultrasonic Seismic and Impact-Echo, particularly when applied together in an integrated instrument such as a Seismic Pavement Analyzer (SPA) or Portable Seismic Pavement Analyzer (PSPA), are high-frequency, acoustic (seismic), geophysical methods. Concrete condition assessment by integrated ultrasonic methods has recently been applied to a number of engineering problems a ssociated with both new and aging concrete structures, but particularly in pavements. However, recent work on evaluating concrete integrity, particularly, looking for the formation of corrosion-induced delamination in early, moderate, and late stages of development, has demonstrated that these integrated methods show considerable promise, in terms of current and potential capability. Figure 67 shows a basic Ultrasonic Seismic and Impact Echo setup.

In the transportation sector, these integrated surveys can be used for quality assurance (QA) verification of new construction (thickness determination and homogeneity of concrete pour, even segregation of aggregates or suspected voids) and calculation of mechanical properties, both on bridge decks and pavements.

Figure 67. Ultrasonic Seismic and Impact Echo test methods (basic setup and measurement).

See Spectral Analysis of Surface Waves and Ultra Sonic Surface Wave Methods for more details on the combined techniques. Also, see Impact Echo and the beginning of Spectral Analysis of Surface Waves and Ultra Sonic Surface Wave Methods for detailed description of Impact Echo, SASW and USW in this application.

Half-Cell Corrosion Potential Mapping

The half-cell corrosion potential method is a geophysical method incorporating a semi-destructive (for the most part, nondestructive) electrical technique for assessing probability of corrosion in existing deck structures based on measuring voltage (electrical potential) between the anode (top mat reinforcing bars) and a reference electrode that is electrically coupled to the bridge deck surface.

The reference electrode is moved to discrete sampling intervals across the length and width of a deck at equal spacing (recommended at 1.52 m, but often applied at 3.05 m to reduce sampling time and lane closures by a factor of four). The voltage reading at each location, in millivolts, is interpreted to signify an indication of the likelihood that corrosion activity is at or near re-determined levels (or corrosion states); the data are typically represented in the form of a plan-view contour plot of the surface of the deck.

Half-cell corrosion potential testing (and contour-mapping) can be an effective way to characterize the onset of corrosion and/or corrosion state that most likely exists within a reinforced concrete deck. Figure 68 shows the setup for this testing method.

Figure 68. Half-Cell Corrosion Potential method (basic setup and measurement).

This method is applied, in practice, only to existing decks, so it is not considered of particular value in initial quality assurance. It could be included as a supplementary NDT method in a baseline condition survey, however, so that a higher confidence level can be maintained in future potential readings that predict corrosion activity states on regions of the deck.

Infrared (IR) Thermography

Imaging using infrared thermography is a nondestructive geophysical approach used with some degree o f accuracy when evaluating the condition of existing bridge decks, specifically for detection of shallow delaminations in bare concrete decks or identification of de-bonded zones at an overlay/deck interface. If it is properly used under all the right conditions, it can be a useful supplement to other NDT evaluations, including GPR.

Typically, it is not suitable as a stand-alone method because there are many variables that affect its performance and objectivity. Because of this, IR thermography almost always has to accompany one or more other NDT techniques and ground truth. Often, it can be used successfully to complement a GPR survey; however, it must be analyzed and processed carefully by someone experienced with both its benefits and pitfalls so that the information is not over-analyzed, over-simplified or (often) over-emphasized. Over-emphasizing IE data, particularly if poor IR survey conditions exist, often results in either a serious over-estimation of defects in some areas and/or a large number of missed defects in others. Subjective engineering decisions, even if they are based on good knowledge of the method and seem the right decisions to make, often over-ride objective ones that affect the outcome of the survey.

IR thermography identifies delaminations and de-bonded areas because it is sensitive to heat differences at the deck surface caused by the uneven rates of warming and cooling (accumulation and dissipation of thermal energy) between mass concrete, air-filled cavities (delaminations or de-bonded areas), and water-filled delaminations or de-bonded areas. Temperature differences on the surface can indicate the location of usually shallow delamination, but other factors affect surface temperature that will be discussed below. Although, in theory, this sounds like an excellent method, it is prone to several problems that reduce it more to a subjective than an objective analysis method.

Its primary advantage is complete deck coverage, along with visual interpretation of the results and isolation of delaminated/de-bonded zones by marking them directly on a map, taking into account distortion from low camera angle. Analysis is fairly straightforward, in principle, and can be reasonably reliable when ideal or very good conditions are present.

Its primary limitations are:

- Unreliability of solar heating to provide even thermal energy input into all areas of the deck.

- Speed of survey is limited to about 3 to 5 km/h, meaning that deck condition (thermal gradient) can change considerably from start to end of the survey, and a very slow-moving "mobile lane closure" is required.

- Effect of shadows from trusses, cables, walls, jersey barriers, and/or overhead decks generally ensure that uneven thermal loading and dissipation are taking place, removing much of the objectivity of the analysis.

- Dissipation of heat at a rapid rate by a mild breeze, particularly if the wind is sporadic with large variations in intensity; heat is removed temporarily at the surface on actual "hot-spots" that are missed as the survey progresses.

- Problems with variations in reflectance from surface materials or surface conditions that can confuse or otherwise complicate the interpretation, such as pavement patches, surface staining from oil or burned pavement, surface 'polishing' of a concrete deck or asphalt overlay, light and dark areas on a deck caused by sunlight and shadow, pavement markings (paint), etc.

- Time limitations brought about because surveys typically must be performed at limited times of the day when conditions are favorable, i.e., a few hours after initial warming of the deck when heat-retention differences at the surface reveal defects (morning hours) or immediately at or after sundown, when deck surfaces rapidly cool in some areas and more slowly cool in others.

Preferred methods to conduct an IR survey are (1) well-planned aerial surveys on selected decks with few of the uneven heating/cooling problems listed above, taken at appropriate times of the day, when wind activity is low; or (2) survey behind a vehicle with an active heating source, which provides even heating to decks that cannot rely on solar-heating for uniform heat transfer. The survey, however, must be limited to single-passes that image only the width of the active heating array, and the vehicle with the IR camera must distance and pace itself accurately at constant distance and speed with the one heating the deck to objectively identify locations with cooling or heat-retention properties indicative of subsurface defects (delaminations or debonding). Clearly, this method is not extremely well suited for providing objective survey results on its own.

Infrared (IR) thermography should not be used as a stand-alone method, and, if considered as an added tool perhaps accompanying GPR, clients would be well-advised to learn as much as possible about the method and the service-provider recommending its use to determine if the combined interpretation weighs IR results too heavily. Because it is widely used in some areas and can be well implemented by some service providers, it is treated as an important geophysical (NDT) method; however, it is not discussed in any great detail, nor will it be recommended as a primary evaluation tool. Additionally, if a combined IR thermography/GPR survey is proposed, but one of the three preferred GPR survey methods is not incorporated with the IR survey, the entire proposal should be considered suspect.

Although the principles for each of the above methods are all fairly straightforward, skilled practitioners with considerable experience will almost always provide better results than those with less, provided they are employing the appropriate methods at the right time. Often, this requires a considerable investment in formal training of appropriate methodologies or techniques for each geophysical method.

Each of the above methods, depending on the desired quality of the investigation, the time required to obtain results, and cost has its merits. However, short-term diagnosis costs or equipment investment should be weighed against the long-term benefits of obtaining better information for deciding appropriate preventive maintenance and maintenance/replacement activities for existing decks, and for evaluating contractor compliance to specifications on new construction.