Concrete structures, such as bridge structures, are normally cast on site using locally available materials. Although the concrete material itself is usually prepared according to careful design and quality controlled by the manufacturer, inconsistencies in the final product may appear due to variations in the quality of the materials. The casting of large volumes of concrete in heavily reinforced and awkwardly configured structures is difficult and not always successful. The uniqueness of most large structures can introduce unpredictable factors that may increase the risk of unforeseen difficulties during pours and the intervals between pours. Innovative techniques intended to make the work more efficient can lead to quality and conformance problems of the finished product. Unfortunately, the outward appearance of the concrete surface may not reveal internal defects.

Quality control of the finished product may be carried out by visual inspection and by performance monitoring, e.g., measuring concrete strain under load or, in the long term, due to creep. The general behavior and appearance of the structure is thus checked. However, critical damage and deterioration to concrete structures are often less dependent on the general condition than on specific defects, particularly in the case of pre- and/or post-tensioned structures or those in a potentially aggressive environment.

For in-service structures, the construction plans and records may not be available. Also, environmental and service conditions may have caused changes in the integrity of the structural components. Concrete has a heterogeneous nature; it is susceptible to change in uniformity and properties, locally at the fresh stage, and, in the long term, due, for instance, to the effects of moisture movement.

Defects in concrete must also be treated from the point of view of engineering significance and not purely on type, size, and position. A nondestructive survey of a large concrete structure must, therefore, be made efficiently, using techniques with predictable behavior, reliability, and capability. The interpretation of the survey results must include an understanding of the significance of defects from an engineering perspective. This requires harmony between structural engineering expertise, preferably with historic knowledge of the structure in question, and inspection personnel with access to nondestructive technology with proven performance for the case in question. Qualitative surveys of concrete are relatively simple to carry out, but usually leave many questions unanswered. Quantitative surveys are possible with the techniques available today, although a key factor is pre-survey information. It helps to know what the problem might be and to then tailor the specific technique to locate the potential problem.

The condition of concrete structures should be tested to:

- Obtain information that can be used in the prediction of service life.

- Determine the ability of the structure to safely handle the design loads or anticipated loads.

- Determine conformance of the "as-built" structure with contract plans, specifications, and approved changes.

The service life of a structure may be affected over time by corrosion of embedded steel. The "as-built" condition of a structure may be different from the contract plans and specifications and approved changes for two reasons: on-site detail changes may not have been recorded, or workmanship-related problems may be present.

In the majority of cases, the more ambitious inspection programs, some of them involving NDT, are initiated by observations of deterioration at a late stage. It may also be necessary to establish parameters, which can be used in load-bearing capacity calculations or simply to determine the position of reinforcement prior to intrusive works.

Extensive cracking of concrete can lead to loss of reinforcement bond, as can settlement of the concrete at its plastic stage during casting. Voids can constitute weak zones and loss of anchorage capacity and, in some circumstances, can lead to serious corrosion of embedded steel.

One problem that has received much attention due to catastrophic failure of some major civil engineering structures is that of corrosion to pre- and/or post-tensioned reinforcing cables or bars. These are normally placed inside ducts, which are either injected with a cement grout or filled with some other corrosion-inhibiting material such as oil or grease. In the former case, there is no possibility of removing the cables for inspection. Voids inside cable ducts may occur due to unsuccessful grout injection, increasing the risk of corrosion to pre-stressed steel. Inspection of these cables requires location, usually behind one or more layers of reinforcing, detection of voids, and inspection of the physical condition of the cables themselves. Table 1 summarizes the potential defect/damage types and problem cases frequently encountered.

Table 1. Nondestructive testing of concrete - point of interest/damage type.

| Item/Object of test | Description |

| 1 | Cracking perpendicular to surface concrete |

| 2 | Cracking (internal) parallel with concrete surface |

| 3 | Deterioration of concrete with time |

| 4 | Damaged (weak) concrete layers |

| 5 | Elastic properties of concrete (E-modulus) |

| 6 | Elastic properties of concrete (G-modulus) |

| 7 | Thickness of concrete member or layer |

| 8 | Voids and inhomogeneities |

| 9 | Reinforcement location |

| 10 | Reinforcement diameter |

| 11 | Damage to reinforcement |

| 12 | Location of pre-stressed cable ducts |

| 13 | Detection of voids in pre-stressed cable ducts |

In the Integrity Section, the techniques that are appropriate for evaluating the condition of concrete in new foundation elements were discussed. If the definition is expanded from concrete foundation elements to concrete structures in general, then other techniques can also be used. This section includes some of these other techniques.

Geophysical methods discussed in Intergrity Testing of Other Bridge Substructure Elements for integrity testing of concrete in foundations are listed below:

- Crosshole Sonic Logging (CSL)/Crosshole Sonic Logging Tomography (CSLT).

- Sonic Echo (SE) / Impulse Response (IR).

- Gamma-gamma Density Logging (GDL).

- Single Hole Sonic Logging (SSL).

- Ultraseismic Profiling (US).

- Thermal Integrity Profiling (TIP).

Methods that are used for concrete structures in general include the following:

- Ultrasonic Pulse Velocity (UPV).

- Impact Echo (IE).

- Ground Penetrating Radar (GPR).

- Spectral Analysis of Surface Waves (SASW) / Multichannel Analysis of Surface Waves (MASW).

In addition to the geophysical methods, there are several methods that use traditional NDT methods. These techniques are listed below. Some of these methods, although providing good results for thin concrete, may not be appropriate for concrete foundations where the method needs to penetrate much thicker concrete.

- High Resolution Acoustic Mapping.

- Neutron Computer Tomography.

- Acoustic Emission (AE) Analysis.

- High Energy Radiography.

- Thermographic Imaging.

- Laser Interferometry.

- X-Rays.

Of the above methods, only Acoustic Emissions and High Energy Radiography are briefly discussed. These are presented merely as examples of the traditional NDT methods and can be used to illustrate the differences between the geophysics and other methods. Non-geophysical methods include the Rebound hammer, core analysis, and Penetration Resistance Probe. These techniques are not discussed in this web manual.

Ultrasonic Pulse Velocity (UPV)

This method is used for computing the ultrasonic pulse velocity of structural concrete. UPV can be used for assessing integrity of structural concrete elements of up to 7.5 m thick with two-sided access. UPV tests can also be performed on wood, masonry, and metal structures.

Basic Concept: This technique involves measuring the travel time of acoustic pulses through material with a known thickness. The frequencies of the transmitted signals vary from 50 to 300 kHz. Under certain conditions, it is possible to estimate the compressive strength using the ultrasonic pulse velocity method. The method requires that objects to be tested have two sides available for access. Voids, honeycomb, cracks, delaminations, and other damage to concrete can be located. This method is used to predict the strength of early stage concrete and as a relative indication of concrete quality.

Data Processing and Interpretation: An example survey is presented in which a concrete column having a cross- sectional area of 1 m was measured. A grid interval of 150 mm by 150 mm was drawn on the surface of the column giving the measurement locations. Figure 30 shows the column and the measuring points.

Figure 30. Measurement points for Ultrasonic Pulse Velocity method. (Rösch, 2003)

Core samples were taken for this particular survey to establish the relationship between pulse velocity and compressive strength of the concrete the results are presented in figure 31.

When applying ultrasonic pulse velocity (UPV) measurements to assess concrete quality in compound units, it is important to base the interpretation on more than just a few measurements. It is also helpful to present the results in a 3-D diagram as shown here.

Advantages: The method has provided reliable in-situ delineations of the extent and severity of cracks, areas of deterioration, and general assessments of the condition of concrete structures. The equipment can penetrate over 90 m of continuous concrete with the aid of amplifiers and is easily portable. Although most surveys are done in dry conditions, the transducers can be waterproofed for underwater surveys. Tomographic inversion techniques can be used for two and three-dimensional imaging of defects by scanning the tested element with many combination of source and receiver measurement locations.

Limitations: The method requires two-sided access of the tested element.

Figure 31. Relation between pulse velocity and compressive strength. (Rösch, 2003)

Impact Echo (IE)

Impact Echo (IE) is an acoustic nondestructive test method used for evaluating concrete, masonry, and timber structures. For bridge substructure investigations, IE tests are performed to assess the conditions of slabs, beams, columns, and retaining walls. IE is also used to assess the integrity of pavements, runways, tunnels, and dams. Voids, honeycomb, cracks, delaminations and debonding in plain and reinforced structures can be found with this method. Thickness measurements are done according to ASTM Standard C 1383-98a.

A team of researchers at the National Institute of Standards and Technology (formerly the National Bureau of Standards) initiated a study in 1983 that developed the rudimentary basis for this method. Subsequently, research carried out at Cornell University, under the direction of Dr. Mary Sansalone, has refined the theoretical basis of the method, extended its applications to a broad spectrum of problems and lead to the development of several field systems.

Basic Concept:The IE tests rely on reflection of compressional waves from the bottom of the structural member or from flaws. An instrumented hammer, or an impactor, is used as a source to generate compressional waves which are sensed by a receiver after being reflected several times. The receiver is typically placed about 5 to 7.5 cm from the impact point. The selection of a hammer versus a smaller impactor depends on the thickness of the member so that appropriate frequencies are generated.

Data Acquisition: In conventional IE tests (figure 32), the hammer or a short duration mechanical impactor is used to generate low-frequency compressional waves (up to about 80 kHz), which reflects back from the bottom of the tested member or from a discontinuity. A receiver, placed next to the impact point, measures the response of the system. The wavelengths of these compressional waves are typically between 50mm and 2000mm which is longer than natural inhomogeneities in concrete (aggregate, air bubbles, micro-cracks, etc.). As a result they propagate through concrete almost as though it were a homogeneous elastic medium.

Figure 32. Schematic diagram of Impact Echo method.

Data Processing: Since the reflections are more easily identified in the frequency domain, the time traces are then transformed to the frequency domain for calculations of the transfer function. Pronounced peaks in the transfer function or frequency spectrum test records typically indicate reflections. These peaks correspond to thickness or flaw depth resonant frequencies.

Data Interpretation: The Frequency spectrum of the receiver is used to determine the depth of reflectors according to:

D = Vp / (2 x fr)

where D is the reflector depth, fr is the large dominant frequency peak identified in the response, and Vp is the compressional wave velocity. f the velocity of the concrete is known or can be measured, then the depth of a reflector can be calculated from the reflection echo peak frequency. The wave speed Vp can be measured by observing the travel time of a compressional wave between two transducers held a fixed distance apart on the concrete surface or by performing a calibration test on a slab of known thickness and observing the dominant frequency.

The highest amplitude frequency peak is the main indicator of a reflector depth (thickness echo). The presence of additional echo peaks can also be significant, indicating the presence of possible defects or other interfaces in the concrete.

Advantages:Similar to Ground Penetrating Radar (GPR), described in Ground Penetrating Radar (GPR), only one-sided access is required for this test.

Limitations: For accurate thickness and flaw calculations, accurate measurement of compressional wave velocity is required.

Ground Penetrating Radar (GPR)

GPR uses electromagnetic wave to assess integrity and thickness of concrete, masonry and timber structures. For concrete structures, GPR can be used to map the rebar and tendons as well as locate voids underneath slabs.

Basic Concept: GPR is most commonly used for evaluating roadbed surfaces (concrete, asphalt) and requires one surface to be exposed. The GPR antenna is placed on this surface to image the internal structure or the other side of the structure. The GPR instrument consists of a recorder and a transmitting and receiving antenna. Different antennas provide different frequencies. Lower frequencies provide greater depth penetration but lower resolution. Figure 33 provides a drawing illustrating GPR reflections from the bottom of a concrete surface and from a defect within the concrete.

Figure 33. Ground Penetrating Radar system over a defect.

Data Acquisition: GPR surveys are conducted by moving an antenna over the surface of the object to be surveyed. The recorder stores the data and may also present a picture of the recorded data on a screen. As with all surface methods, source and receiver locations must be accurately surveyed.

Data Processing: It is possible to process the data much like the processing done on single channel reflection seismic data. However, this may not be necessary since the field records may be of sufficient quality that they satisfy the survey objectives without further processing.

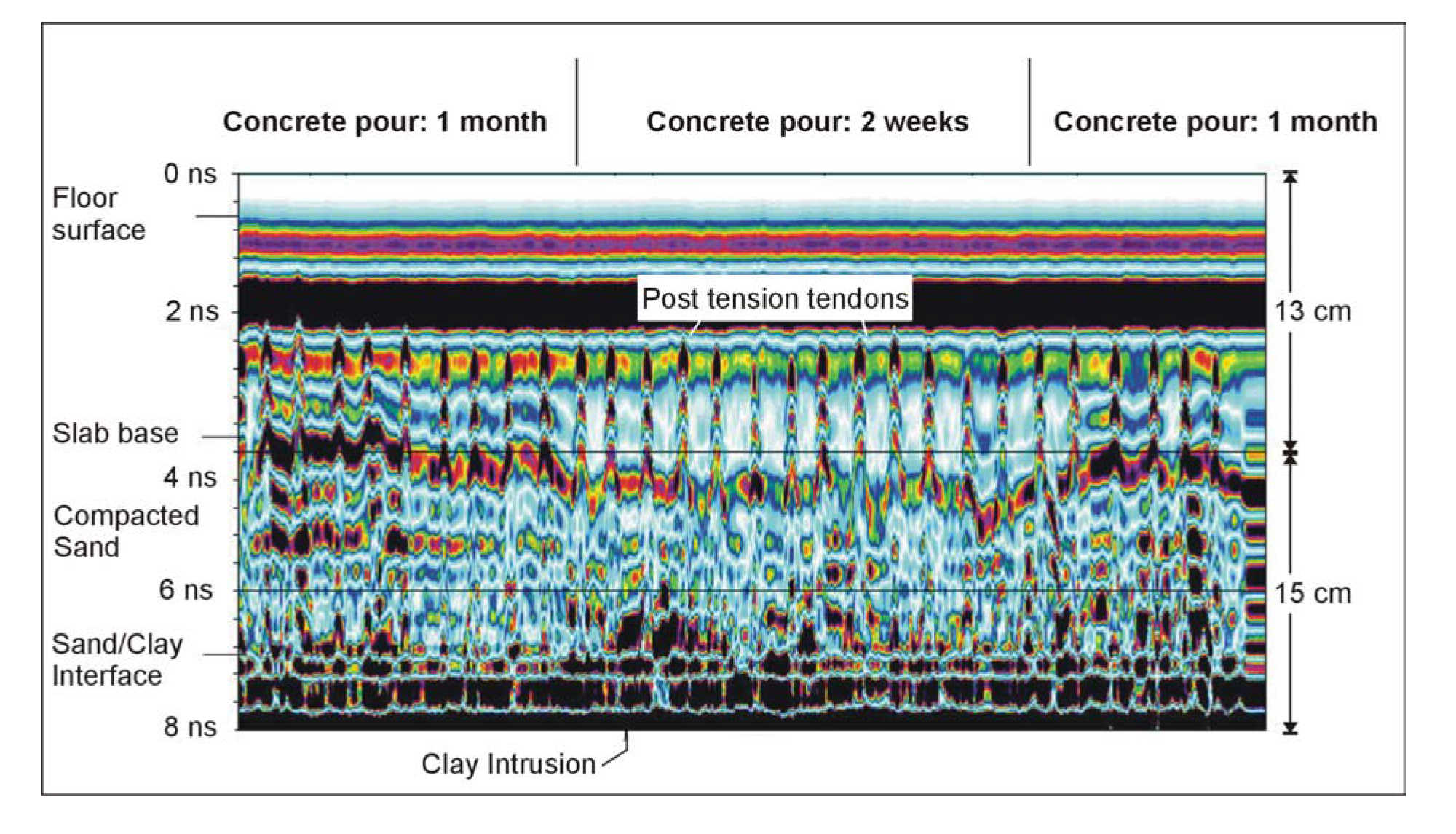

Data Interpretation: GPR data are usually interpreted by visually inspecting the records and recognizing the events. Figure 34 shows GPR data from a post-tension tendon survey at two different times after the concrete pour. In this case, the penetration of the signals was to a depth of about 20 cm.

Figure 34. Plot of Ground Penetrating Radar data from a post-tension tendon survey.

Advantages: This is a quick and economical test method used for condition evaluation and high-resolution imaging inside or below structures. Only one-sided access is required for this method.

Limitations: The depth of penetration depends on the frequency of the GPR signal used and the resistivity (or its inverse, conductivity) of the material being investigated. Since the higher frequencies provide better resolution, the objective is to use a frequency as high as possible, consistent with the required depth of investigation.

Concrete may have resistivities that vary substantially depending on the amount of moisture it contains and the salt content of the moisture. Concrete that contains a significant amount of saline water will have much less penetration than dry concrete.

Spectral Analysis of Surface Waves (SASW)

SASW is a surface wave method used for determination of layer thickness, velocity (stiffness), and integrity of concrete, asphalt, timber and masonry structures.

Basic Concept: This method is based on the propagation of mechanically induced Rayleigh waves. By striking the concrete surface with a light hammer, a transient stress wave is created (surface or Rayleigh), which is registered by two transducers placed in line with the impact point on the ground surface at fixed separations. The transducers, which may be small accelerometers, register the passage of the waves. The receiver outputs are plots of the phase difference between the two transducers as a function of frequency. A profile of Rayleigh wave velocity versus wavelength, or so-called dispersion curve, is calculated from the phase plot. The ratio of Rayleigh wave velocity to shear wave velocity is approximately 0.9:1; thus, the shear wave velocity can be estimated. The shear stiffness (G) of the concrete can be calculated from the shear velocity if the material density is known, and a plot of ground stiffness as a function of depth from the surface can be obtained.

Rayleigh waves have velocities that depend on their wavelength, a phenomenon called dispersion. Waves having different wavelengths sample to different depths, with the longer wavelengths sampling to greater depths. Figure 35 illustrates the sampling depths and particle motion of two Rayleigh waves having different wavelengths.

This principle is used to measure the thickness of ground layers with different stiffness properties. It can also be used to locate and roughly delineate inhomogeneities such as voids.

Figure 35. Schematic showing variation of Rayleigh wave particle motion with depth.

Data Acquisition: The surface wave dispersion curve can be measured using an active source and a linear array of receivers. The dispersion curve is then inverted to determine the corresponding shear wave velocity profile.

The two main methods used in surface wave exploration are SASW testing or array methods. The field setup is shown in figure 7. Either a transient or continuous point source is used to generate Rayleigh waves, which are monitored by in-line receivers. The data acquisition system calculates the phase difference between the receiver signals. These phase data are processed later into the dispersion curve, which is modeled analytically to determine a compatible shear wave velocity profile for the site. The data acquisition system is discussed in more detail below.

The source used depends on the desired profiling depth - heavier sources generate lower frequency waves that provide deeper interpretations. A combination of sources is commonly used to measure dispersion over a broad enough bandwidth to resolve both the near-surface and greater depth. Transient sources include sledgehammers (<15 m depth) and dropped weights. Continuous sources include the electromagnetic vibrator (< 40 m depth), eccentric mass oscillator, heavy equipment such as a bulldozer (30 to 150-m depth), and the vibroseis truck (<120 m depth). A pair of vertical receivers monitors the seismic waves at the ground surface. For profile depths of approximately 100 m, 1 Hz geophones are required. Five or 10-Hz geophones can be used for surveys from 10 to 30 m deep. Theoretical, as well as practical, considerations, such as attenuation, necessitate the use of an expanding receiver spread. Data are recorded using sources on both sides of the geophone array, called the forward and reverse configuration (figure 36).

Figure 36. Basic configuration of Spectral Analysis Surface Waves measurements.

Data Processing: In the SASW method, a Fast Fourier Transform (FFT) analyzer or PC-based equivalent is used to calculate the phase data from the input time-voltage signals. Typically, only the cross power spectrum and coherence are recorded. Coherent signal averaging is used to improve the signal-to-noise ratio. The availability of either two- or four-channel analyzers has traditionally limited the number of receivers used. Because of the initial processing done by the analyzer in the field, the effectiveness of the survey can be assessed and modified if necessary. An initial estimate of the VS profile can be made quickly.

Data Interpretation: Interpretation consists of modeling the surface wave dispersion to determine a layered VS profile that is compatible. Interpretation can be done on a personal computer.

The acquisition and processing techniques of SASW methods do not separate motions from body wave, fundamental mode Rayleigh waves, and higher modes of Rayleigh waves. Most often, it is assumed that fundamental mode Rayleigh wave energy is dominant, and forward modeling is used to build a 1-D shear wave velocity (VS) profile whose fundamental mode dispersion curve is a good fit to the data.

Advantages: This method provides for layer thickness profiles as well as stiffness. For slabs and pavements, velocity profiles including the surface layer, base and subgrade materials within 5% accuracy. Only one-sided access is required for this method.

Limitations: This method does not isolate fundamental mode Rayleigh waves in determining the velocity dispersion curves. The depth of penetration is determined by the longest wavelengths in the data and is site dependent. In modeling, there is a trade-off between resolution (layer thickness) and variance (change in VS between layers). Data that are noisier must be smoothed and will have less resolution as a result. Whether a particular layer can be resolved depends on its depth and velocity contrast. The modeled VS profile is insensitive to reasonable variations in density. VP cannot be resolved from dispersion data, but has an effect on modeled VS. The difference in VP in saturated versus unsaturated conditions causes differences of 10% to 20% in surface wave phase velocities, which leads to differences in modeled VS.

The depth of penetration is determined by the longest wavelengths that can be generated by the source, measured accurately in the field, and resolved in the modeling. Generally, heavier sources generate longer wavelengths, but site conditions are often the limiting factor. Available open space determines the offset from the source and aperture of the array, which determines the near-field wave filter criteria. Commonly, wavelengths are removed from the data that are longer than twice the distance from the source to the first receiver. Attenuation characteristics of the soil and overburden determine the signal level at the geophones. The cultural noise (traffic, rotating machinery, etc.) at a site may limit the signal-to-noise ratio at low frequencies. In SASW methods, the depth of resolution is usually one-half to one-third of the longest wavelength.

The field setup requires a distance between the source and most distant geophone of two to three times the resolution depth. However, forward modeling allows for subjective interpretation of the sensitivity of the dispersion curve to the layered VS model. Resolution decreases with depth. A rule of thumb is that if a layer is to be resolved, then the layer thickness (resolution) should be at least approximately one-fifth of the layer depth.

For investigations of thin concrete structures, the presence of rebar will probably influence the data.

Acoustic Emissions (AE)

This method makes passive measurements of acoustic waves generated from cracks inside a concrete member that is undergoing stress.

Basic Concept: An acoustic emission (AE) is the stress wave that results from cracks and other dynamic sources within a material. These stress waves can be detected at the surface of the structure, and can be analyzed to evaluate properties of the cracks that generated the event. Acoustic emissions (AE) have been shown to detect film cracking, gas evolution, and microcracking. It is also used to detect rebar corrosion. Field use of the AE method has been somewhat limited due to the highly attenuative nature of concrete.

The AE method measures the high-frequency acoustic energy that is emitted by an object that is under stress. Slow crack growth in ductile materials produces few events, whereas rapid crack growth in brittle materials produces a significant number of high amplitude events. Corrosion product buildup and subsequent microcracking of the concrete represents the latter phenomenon.

Data Acquisition: A typical AE monitoring system uses piezoelectric sensors acoustically coupled to the test object with a suitable acoustic coupling medium (grease or adhesive). A multi-channel transient sonic recorder with sampling rates of up to 10 MHz is added. The output of the sensors is amplified and filtered by pre-amplifiers and fed to the monitor via shielded coaxial cables. The monitor further filters and amplifies the AE signals, processes the data, and displays the results. Both results and raw data are typically recorded for archival purposes or for post-test analysis to determine location of the AE signal.

Data Processing and Interpretation: The evaluation of AE data has evolved from simply counting the acoustic emission events to the extraction of the signal parameters, like rise time or energy, to the use of several transducers to localize the event origin. Finally, geophysical algorithms are now being used to invert for crack types, orientation, and energy.

Advantages: Although the application of AE in concrete structures is relatively new, it is frequently applied in traditional NDT field for metals and compounds.

Limitations: Due to the complicated structure of the material, its application to concrete is not yet well established; although the progressive automation of the method will increase considerably its applicability and acceptance.

High Energy Radiography

The method involves producing high-energy X-ray beams to produce a high-resolution picture of the object that is imaged.

Basic Concept: Concrete coring and sawcutting can be risky, especially when the interior reinforcement structure is unknown. In many cases, the risks can be eliminated by using x-ray techniques prior to coring or sawcutting in order to locate rebar, post-tensioned cable, and conduit.

Data Acquisition: One particular instrument is called a Portable X-Ray Betatron (PXB) and produces X-Ray beams with an energy level of 7.5 Mev. With this energy level, the beams can penetrate thick concrete and reveal flaws inside the concrete structure. Figure 37 shows the instrument setup.

Figure 37. High Energy Radiography equipment and operation (Forced Technology)

Data Processing and Interpretation: Where the structure can be accessed on both sides, a 3.6 m x 4.3 m film is positioned on the opposite side of the structure to be examined to a depth up to 56 cm. X-ray computed tomography (CT) technique is now being used in concrete cylinders for a nondestructive visualizing of the aggregates used in the concrete. From a 3-D multi-aggregate image, individual particles can be extracted by this method.

Advantages: X-ray produces the highest quality NDT image of the interior structure of concrete.

Limitations: Special licensing is required by the State Radiological Health Department. For highly occupied sites such as hotels, hospitals, casinos, etc. where evacuating of two floors to perform x-ray inspections is impractical may require an alternate inspection method, such as GPR discussed in Ground Penetrating Radar. GPR is also the method of choice for slabs on grade, retaining walls, and other conditions where only one-side accessibility is available.